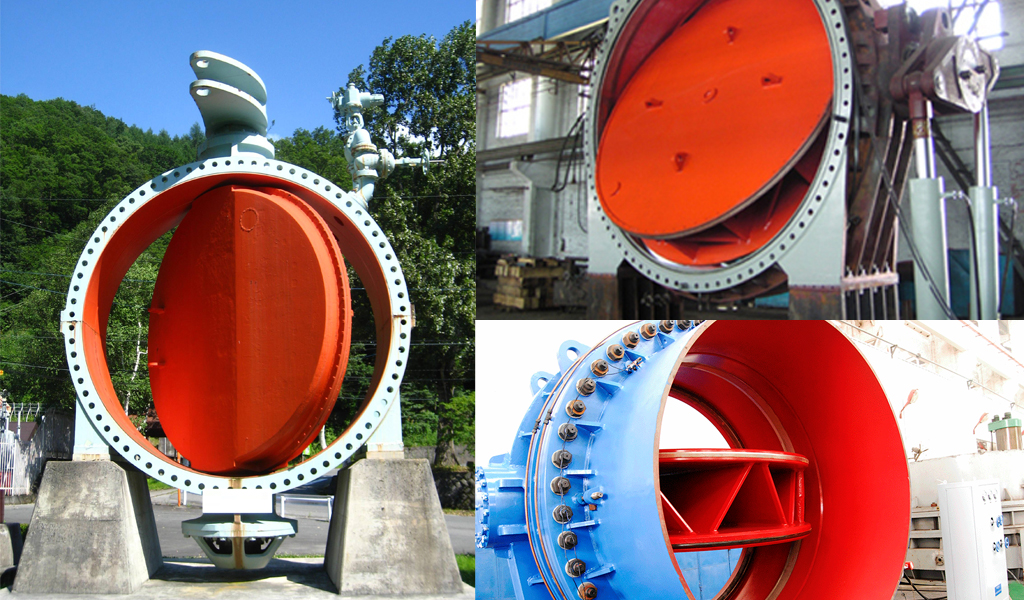

Our butterfly valves have been very commonly used in various water supply and other industrial services, irrespective of sizes, pressure ratings, fluids handled, type of operators etc. our BF valves are the most preferred choice of the discerning customers. We have also kept our valves in tune with the latest technological advancements in materials, manufacturing, pattern making & foundry & operators fields.

This has enabled us to offer valves in Cast / fabricated constructions in Cast Iron, Carbon & Alloy Steels & Stainless Steels & also rubber-lined variety.

The types of operators offered are Manual, Electrical, and Pneumatic & Electro- Hydraulic.

Features:

- Easy and quick opening and closing. Small fluid resistance. It can be frequently operated.

- Simple structure, small size, and light weight.

- It can transmit mud, and has the least amount of liquid accumulated at the outlet of the pipeline.

- Under low pressure, good sealing can be achieved.

- Good regulating performance.

Special Features of Center Disc Design

- Lower Torque: There is no frictional contact between disc and rubber seat, which makes frictional resistance almost close to zero, thus markedly reducing operating torque.

- Low Torque with any fluid: There is no point at which frictional resistance occurs. Therefore, torque is always low regardless of the fluid, air water or Oil.

- Long Service Life: When the disc contacts the tapered projection of the rubber seat, a complete seal, is attained, which results in long service life.

- Greater Sealing Capacity: The dynamic seat means the greater pressure and betters the sealing.

- Bi- directional zero leakage butterfly valve.

- Accurate Dual stem sealing and Quarter turn operation for excellence flow control.

- Compact space saving design.

- Seat integrally molded with the body.

- Sturdy & robust construction.

- Disc assembly perfectly centered & secured in valve Body bore.

- Flow through disc ensuring minimum pressure drop.

- Compliance with: IS 13095, AWWA C504, BS 5155 standards.

Wafer-lined Butterfly Valves

- Liner locked in precision machined grooves in valve body.

- Sealing ribs on end faces with enough protrusion to ensure drop-tight end face joints.

- Sturdy & long shaft bearings ensuring precise rotation of the disc assembly in the body.

- Double shaft seal which precludes leakage possibility.

- Robust Hand Lever mechanism without backlash & possibility of over-travel due to provision of in-built, positive travel limit stops.

- Possibility of offering Electrical / Pneumatic actuator.

- Optimized liner dimensions ensuring efficient sealing performance.

- Critically controlled interference between the Rubber liner & the Disc sealing surface ensuring leak-

- tightness & lower operating torque at the same time leading to long seal life.

Wafer Type

Our valves are designed to meet the demanding requirements of the general utility valve market. These valves are truly fit & forget valve, which requires minimal maintenance.

The body liner which also functions as the soft seat comes in an integrally molded (bonded) version and offers 100% bi-directional sealing against vacuum to rated pressures of PN10.The wafer style body has universal design to fit between pipe flanges of almost all popular flange standards.

Confirmation of codes & Standards

General design and manufacturing : API 609 category A / BS 5155 / MSS SP-67

Valve face to face dimension : Short wafer as per ISO 5752 Tab 5 / API 609 category A

Top flange drilling : ISO 5211 part II

Valve inspection and testing : API 598

Flange standard conformity : ANSI 150 , DIN PN6 / 10,BS10 Tab D & E, IS 6392 NP 0.6 / 1.0

Technical Specification

- Valve type : Centric Disc Butterfly valve with a single piece Rubber lined body

- Body type : Short wafer (sandwiched between flanges)

- Seat type : Integrally moulded with the body.

- End Connection : Wafer Sandwiched

- Size range : 40 NB to 300 NB

- Pressure rating : PN 10 / PN 1

- Operating temperature range : -25 C to 130 C (depending on MOC)

- Seat leakage : Tight shut off

- Operation : Hand lever for sizes from 40 NB to 250 NB Worm gear boxes for 40 NB to 300 NB.

- Standard Material of Construction (MOC)Valve

Body : CI / SGI / WCB

Disc : SGI / WCB / CF8 / CF8M

Seat : Nitrile / EDPM / Neoprene / Hypalon

Bearing : AISI410 / SS 17.4 PH / SS 316 Steel+PTFE or SS316+PTFE

Key Features

- Integrally molded seat liner on the body, which ensures excellent dimensional stability & guaranteed seat tightness.

- Seat liner extending on to the contact faces ensures perfect sealing and eliminates the need for separate flange gaskets.

- Narrow land disc ensures perfect sealing with least operating torque requirements.

- A fully universal body design ensures fitment of the valve between companion flanges of all popular standards

- A ten position notch disc and hand lever ensures locking of the valve in 8 intermediate positions in addition to closed and open position. Hand lever lockable through pad lock for tamper proof positioning.

- Valve disc made of ductile cast iron instead of cast iron to withstand against possible water hammer or pressure surges.

- A truly line size body bore to ensure maximum flow capacity with the lowest pressure drop.

- Shafts made of martensitic stainless steel to ensure maximum strength and torsional rigidity.

- Both top and bottom shaft swiveling are guided by self – lubricated PTFE bearings.

WAFER TYPE BUTTER FLY VALVE

LUG TYPE BUTTERFLY VALVE WITH LEVER & GEAR OPERATED

BUTTER FLY VALVE DOUBLE FLANGED WITH LEVER & GEAR OPERATED

Wafer Type Offset Butterfly Valve With Lever Operated

BUTTER FLY VALVE DOUBLE FLANGED OFFSET WITH LEVER OPERATED